On February 10th, 1903, The L.C. Smith & Brothers Typewriter Company bought a Washington and Almond Street site for their factory. Shortly after, Timothy L. Woodruff was selected as president of the company. Woodruff had previously served as Lieutenant Governor of New York State under three different governors (the only person in NYS history to do so), including Theodore Roosevelt. The company stayed on this site until 1962 when it was replaced with an office building called Midtown Plaza that housed Onondaga Community College for a decade. Now, the location is the site of the Center of Excellence building.

More about The L.C. Smith & Brothers Typewriter Company:

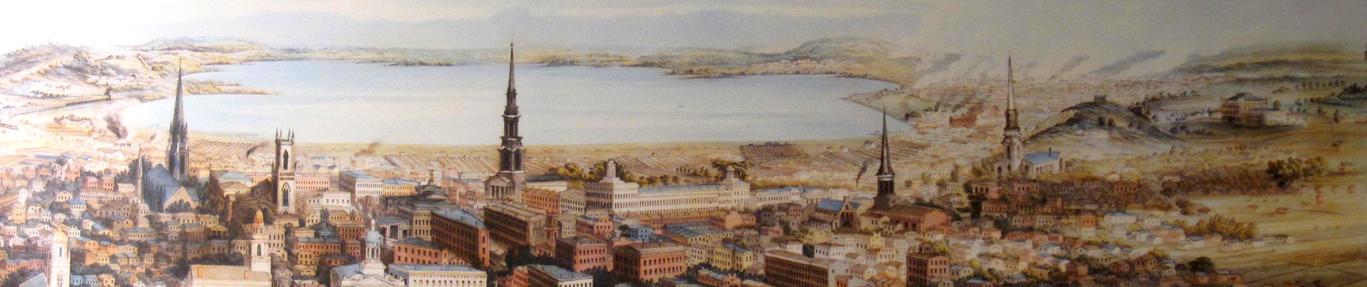

At the turn of the 20th century, along with being known as the Salt City, Syracuse was also known as the Typewriter City, because typewriter factories were a common sight throughout the city. One of those factories was L.C. Smith & Bros. Four Smith brothers – Lymon C., Wilbert L., Monroe C., and Hurlburt W. – founded L.C. Smith & Bros. Typewriter Corporation in 1903. But the Smith brothers’ rise to become one of the largest typewriter companies in the world started in a rather unconventional manner. Lymon Smith, who moved to Syracuse from Lisle (Broome County), NY, founded a shotgun factory with his brother Leroy and a talented gun designer, William Baker, in 1877, known as W.H. Baker and Co.

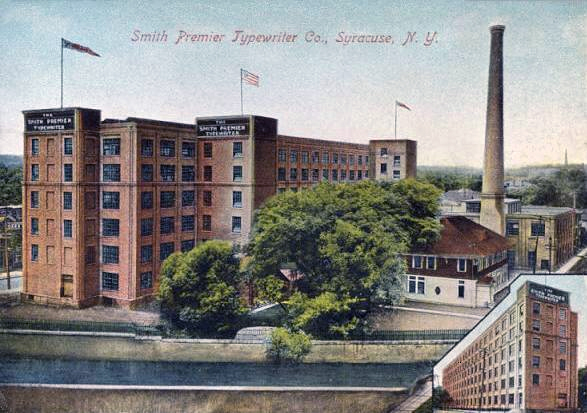

Three years later, Baker and Leroy Smith left the company and went to Ithaca to establish the Ithaca Gun Co. Lymon stayed in Syracuse and continued making the Baker shotgun with his brother Wilbert, under the name, L.C. Smith, Maker of the Baker Gun, Syracuse, NY. One of Smith’s employees, the brilliant and entrepreneurial Alexander T. Brown, developed the notable L.C. Smith breech-loading shotgun, which became a very popular firearm and made the company a great business success. While experiencing a financial windfall with his shotgun, Smith allowed Brown to experiment with a recently developed typing machine. Brown’s tinkering led to him creating the Smith Premier typewriter in 1886, the first typewriter to print both upper and lower case letters. Recognizing the potential of far greater financial rewards by making and selling typewriters, Smith sold the shotgun factory in 1889 and poured additional capital into the new Smith Premier Typewriter Company. In 1903, the Smith brothers formed L.C. Smith & Bros Typewriter Company.

The company became tremendously successful, and by 1911, the manufacturing plant, located at 701 E. Washington Street in Syracuse, doubled in size. In 1926, L.C. Smith & Bros. merged with Groton-based Corona Typewriter Company to become L.C. Smith & Corona Typewriter Company. The merged company made office machines in Syracuse and portable typewriters in Groton. By 1936, L.C. Smith & Corona employed over 4,000 people in its factories in Syracuse, Groton, Cortland, Geneva, and Aurora, Illinois. At that time, the company also made Corona adding machines in Groton, Vivid duplicating machines in Cortland, typewriter type in Geneva, and accessories and supplies in Illinois.

As the U.S. entered World War II, L.C. Smith & Corona mimicked several other Onondaga County businesses by re-tooling to make war-time products. In the fall of 1941, the company received its first war contract to produce primers for bombs at the Syracuse factory. In February 1942, the company received a war production conversion order from the U.S. government, to begin making munitions. By this time, L.C. Smith & Corona already had about forty government war production contracts and was ready to further curtail typewriter production in favor of making war products. David Nelson, head of the War Production Board (WPB), expressed an appreciation for the speed with which the typewriter industry “snapped into the war stride.” On March 6, 1942, the WPB froze the sale and delivery of all typewriters. Typewriter production gradually diminished through the spring and summer, and in October 1942, the WPB discontinued all typewriter manufacturing.

Even before the conversion order to discontinue making typewriters, L.C. Smith & Corona became a prime contractor to make the Springfield M1903A3 bolt-action rifle, which although used mainly during the early 20th century, remained a standard issue infantry rifle during World War II. Private companies such as Remington Arms in Ilion, NY and L.C. Smith & Corona made thousands of these rifles for the military. At peak production, the Syracuse factory made 23,000 rifles per month. The company not only made the rifles at the Syracuse factory but they also tested them there as well, firing the rifles deep within the innards of the factory. Along with making the bomb primers and rifles, employees at the Syracuse factory also made parts for pistols, machine guns, and torpedoes, amounting to over 64 million parts made during the war.

Another interesting war product that L.C. Smith & Corona made was the M209 Hagelin cipher machine. Developed by Boris Hagelin of Sweden in 1940 for the U.S. Army, the M209 Hagelin was a portable, hand-cranked encoder that created coded messages. While not as robust as other encoding machines, the signal corps used the M209 Hagelin to create time-sensitive messages that were no longer necessary after a couple of hours. L.C. Smith & Corona made approximately 140,000 encoding machines under a license provided by the Hagelin Company before it was discontinued in 1962.

Although the federal government had ceased production of typewriters in late 1942, it subsequently realized that there was a shortage of 600,000 typewriters needed for military use. At first, the remedy for obtaining additional typewriters was to redirect machines already in the military’s possession, then to purchase used typewriters owned by private companies. The government also asked civilians to give up one in four typewriters to add to the inventory. Although the military obtained several thousand typewriters this way, it fell far short of its goal. Pressure mounted to manufacture new typewriters once again and L.C. Smith & Corona officials made plans to convert their Syracuse factory back to making typewriters. Along with needing additional typewriters, the military started issuing the M-1 Garand and carbines to the infantry. These semi-automatic weapons began replacing the M1903A3 bolt-action rifle made by L.C. Smith & Corona. By November 1943, the government terminated the rifle contract and typewriter production resumed in Syracuse. In December, Major General L.H. Campbell, head of the ordnance department, wrote a letter to Hurlburt W. Smith, president of L.C. Smith & Corona:

“The approaching termination at your plant of the manufacture of the 1903-A3 army rifle will bring to a close a most valuable war emergency contribution by every one of you at L.C. Smith & Corona Typewriter Co. In behalf of the ordnance department may I congratulate you and all your skilled people for your excellent work in tackling boldly an unfamiliar type of production, following thru and providing your troops and those of the United Nations with accurate reliable rifles.”

The company took advantage of the re-conversion to purchase more modern equipment from the government and by February 1944, the company was back to a 50% production rate. War production was also suspended at the Groton factory in 1943 but only for two months while employees at that factory made much-desired portable typewriters for the U.S. Navy. Once reaching the quota for portable typewriters, the company returned to making war products until the end of the war. After VJ Day, the Groton factory converted back to making portable typewriters and adding machines for civilian and business use.

Company officials expanded the Groton factory in July 1945 and, in August of that year, began constructing an eight-story, block-long addition to the Syracuse factory, adding almost another 125,000 square feet of design, manufacturing, and office space on E. Washington St. In 1946, the company changed its name to Smith-Corona and began to identify all its office and portable typewriters and adding machines as Smith-Corona. In 1953, the company modified its name to Smith-Corona, Inc.

After World War II ended, and U.S. companies returned to civilian business, Smith-Corona focused on making its typewriters more comfortable and efficient for the typist. In January 1955, Smith-Corona, Inc. was described as “a stalwart of Syracuse’s industrial economy for more than half a century, and one of the world’s foremost typewriter manufacturers, [which] employs 1,500 in Syracuse.” That same year, the company introduced an electric office typewriter. In October 1956, the company introduced a portable electric typewriter. This new portable weighed almost nineteen pounds and cost just under $200. The company marketed the portable electric typewriter to small businesses and home typists.

In June 1958, Smith-Corona, Inc. merged with Marchant Calculators to form Smith-Corona-Marchant (SCM). Through this merger, the company became more diversified and competitive, with sales more than doubling that year from $40 million to over $85 million.

To meet the demand for its portable typewriters, SCM broke ground in Cortland, NY in 1958 for a new typewriter manufacturing plant. Company officials expected an additional 600 employees to work at the new factory. At that time, SCM employed about 2,500 at its Groton and Cortland sites.

By May 1960, SCM began to move its typewriter production to the Groton and Cortland factories, eliminating all typewriter manufacturing in Syracuse. Mayor Anthony Henninger “expressed shock and disappointment over Smith-Corona’s announcement it would move out of Syracuse.” With this transfer to the other factory sites, the final vestige of the once notable typewriter industry left Onondaga County. Elwyn Smith, SCM president, said the company was diligently looking for a new business to occupy the Syracuse factory site on E. Washington St. It didn’t take long for SCM to find a new buyer for the typewriter complex; by July 1961, SCM had sold it to Anthony Bersani, president of Bersani Realty and Construction Co., who planned to remodel the building and convert it to an industrial arts and commercial center at a cost of $250,000.

In less than a year, Bersani had transformed the former SCM factory into Midtown Plaza, 285,000 square feet of rentable office space that little resembled the former manufacturing site, offering a dramatically altered interior and exterior. The building doubled the space of the two largest buildings in downtown Syracuse. In September 1961, 95% of the space was already rented. Onondaga Community College’s first classes were held there in 1962. After its initial success, Midtown Plaza was sold to a NJ firm, became embroiled in back taxes owed to the city of Syracuse, and eventually became a vacant eyesore. The building was imploded in 1999, and ten years later, Syracuse University’s Center of Excellence opened on the site.

In the mid 1970s, SCM discontinued making manual and electric office typewriters and concentrated on making portable and compact electric machines. In the mid 1980s, along with its typewriters, SCM offered word processors so it could compete with the burgeoning personal computer market. SCM then offered its own version of a user-friendly personal computer known as Simply Smart. The company didn’t forego its line of typewriters and word processors, and believed that these machines would still be viable typing options in the future. However, the handwriting was on the wall for SCM. With the growth of the personal computer market and competition from foreign competitors, SCM’s finances dwindled. To further reduce production costs, SCM moved its manufacturing division to Mexico in 1992. Two years later, citing ongoing poor sales and lower competitor prices for typewriters and word processors, SCM moved its entire operation to Mexico. When SCM declared bankruptcy for a second time in 2000, the company was restructured into a thermal label and ribbon manufacturer with its current headquarters in Cleveland, OH.

Thomas Hunter

Curator of Collections

Onondaga Historical Association